Why Roll Waterproofing is Complex?

Roll waterproofing is a complex work on the installation of a waterproof coating. It mainly isolates underground parts and buildings’ roofs from groundwater penetration or precipitation. Works are carried out with sheet material rolled into rolls. Therefore, this type of waterproofing received such a name. This is the most popular type of external protection and has a wide application around the world.

Top general contractors NYC With a professional approach to the choice of materials and quality work, the service life reaches 20+ years.

Which roll material is better?

Roll insulation is a waterproof sheet designed to protect against water penetration. It consists of a supporting base, which is coated on both sides with a binder and has several mounting methods.

Designed for waterproofing:

- roofs

- foundations

- basement walls

- overlapping

- pools

- main pipelines

- bridges

- underground structures

There are many manufacturers and options for commercial waterproofing services. The choice should be based on site-specific conditions and requirements for long-term protection against water intrusion.

The main characteristics of roll waterproofing:

- without base, roofing felt, programming (roofing cardboard), fiberglass, fiberglass, or polyester.

- The composition of the waterproofing (binder) substance. Can be: bitumen, bitumen-polymer, polymer.

- Mounting method. They can be: glued on special mastics, welded by heating, and self-adhesive.

- The presence of surface dressing refers to bitumen and bitumen-polymer. Depending on the purpose, they are distinguished without sprinkling: coarse-grained, medium-grained, fine-grained, pulverized, or scaly.

If we compare all the options for roll coatings in terms of quality, durability, and cost, we get the following rating:

- The lowest place is occupied by products based on the roofing material, roofing felt, glassine, and bituminous binders. Low price. Poor quality, water resistance period: 1-3 years.

- The most popular category is based on fiberglass, with a bitumen-polymer composition of insulating substances. Low-mid price category. The average level of quality and the period of water resistance of the material is 7-10 years.

- The most expensive category, among bitumen-polymer, coatings based on polyester. As a rule, it is produced with an excellent bitumen-polymer composition of insulating substances. Medium-high price category. Medium-high quality level, water resistance period 10-25 years.

- The benchmark for durability is polymer roll coatings – PVC membrane. This is roll-sheet insulation; installation is carried out on special fasteners. The sheets are soldered with hot air, forming a very reliable solid sheet. High price category. High level of quality, water resistance up to 40 years.

Roll products on bituminous binders, without polymers, and on an organic basis: roofing felt, parchment, and roofing felt are of poor quality. These are unreliable materials as they decompose in the ground if used below the surface. When used on the roof, they melt in the sun, tan in frost, and quickly lose their waterproof properties. But a significant plus is the low price. We do not recommend using this category of materials as they will not provide long-term waterproofing.

The category of insulation is entirely polymer-based, very reliable, and durable. Technologically, it is allowed to work in the rain and with a damp mounting surface. It is essential to use high-quality materials and responsibly perform work. In this case, it is enough to use one layer of PVC membrane to insulate the roof. Therefore, despite the high cost per m2 of PVC materials, the cost of work and materials is comparable to the use of bitumen-polymer. But, if everything is done correctly, you can significantly win the quality of the resulting roofing.

Among bitumen-polymer, polyester-based materials will be the best choice in terms of durability. This type has an increased elasticity of the canvas, and it can stretch. Due to this, the thermal expansion of the building and roof is compensated, and the seams retain their tightness for a long time. The price is higher than the material of fiberglass and fiberglass.

We recommend using materials from the category of bitumen-polymer material based on fiberglass. This is the most widely used rolled waterproofing. In case of increased water tightness and service life requirements, we recommend using a PVC membrane. This is the most durable technology.

Which mounting technology to choose?

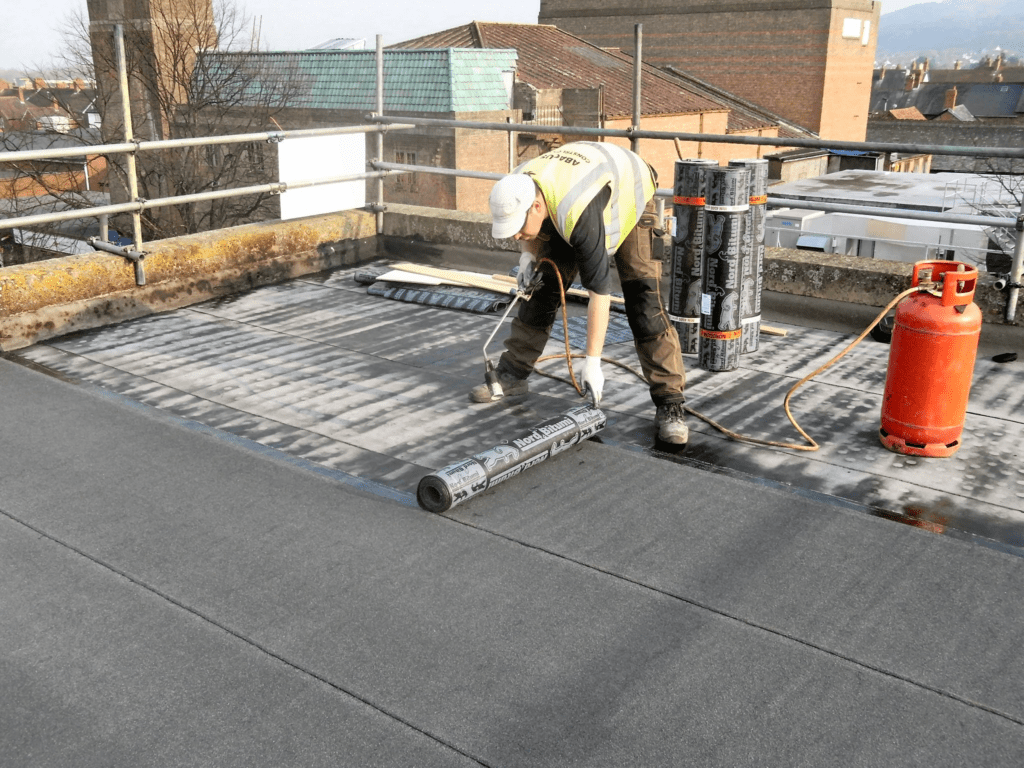

There are two primary installation methods for the bituminous rolled products: pasting and fusing. The self-adhesive method is rarely used, for example, when it is necessary to work indoors or when laying on combustible surfaces.

Regardless of whether the application surface is vertical or horizontal, deposition technology is predominantly used. This is a more reliable technology for waterproofing Contractors NYC. It is explained by the fact that it repeats the curves of the surface with greater accuracy, and the uniformity of the binders provides a firmer grip in contrast to the gluing technology, which uses an intermediate layer in the form of bituminous glue (mastic). Also, the built-up installation method is faster, which allows you to offer a lower cost for work.

Self-adhesive roll coatings are more expensive; their installation requires more time than fusing technology. This installation method has lower adhesion to the surface, which leads to a loss of laying quality on vertical surfaces. The application is recommended for flat roofs with small amounts of work.

Marking – instructions for use.

When purchasing materials, you need to know products’ labeling and decoding. These designations define the technology of waterproofing works and indicate distinctive features.

Marking example:

- lining

- roof installation NYC

- fiberglass

- Polyester.

Each marking corresponds to its purpose or conditions of use.

Roll coatings for waterproofing foundations and basements.

Roll insulation is considered a universally recognized means of protecting the foundation and basement from water penetration. But this waterproofing has a severe risk to its suitability in the environment of soils saturated with acids and alkalis!

Firstly, bitumen is an organic substance, and under the conditions of an active micro-organic environment of the soil, it is exposed to the aggressive action of bacteria and microorganisms. Secondly, when the material is exposed to the chemical composition of the soil, it loses its waterproofing properties. Therefore, you need to take the issue of choosing a roll coating for waterproofing the recessed parts of the house seriously. The materials must contain special polymeric modifiers, plasticizers, and antibacterial additives. Using such coatings, you can count on reliable and long-term waterproofing.

The technology of laying waterproofing in two layers :

Important:

Calculating the necessary material for the work is carried out with a margin. The amount should be 15-20% more than the coverage area. This is due to the need to overlap the insulation and the inevitable formation of scraps of material. Trimmings are not suitable for installation, the more, the more complex the work surface.

Algorithm and content of waterproofing works

Preparing the base for laying

The preparatory stage of work is as essential for a quality result as the process of installing waterproofing itself. This stage of work is the key to long-term and reliable protection against water leaks. Any significant irregularities, chips, cracks, or surface defects must be repaired using a cement-sand mixture. If necessary, preliminary jointing of defects is done with a perforator, and a fillet is made at the corners of perpendicular surfaces. The surface is thoroughly cleaned from sand, dust, and dirt.

Application of bituminous primer

The surface leveled from defects is treated with a bituminous primer, which is necessary to increase adhesion between the rolled material and the structure. It is applied with a roller in one layer. We are against the recommendation that diluted bitumen can be used instead of a primer. Poor-quality bitumen instead of a special primer can not only not help but also harm the quality of waterproofing work.

Overlapping

The laying of the roll material must be overlapped. Docking along: the first canvas, covered by the next one by 10 cm. Perpendicular joints (end): the first canvas, covered by the second by 15 cm of the canvas. The amount of overlap increases with the presence of a slope and the complexity of the surface to be covered. In these cases, the value can be 20 cm – 25 cm.

Fusion of the first layer (lining)

When working on horizontal surfaces, one person can easily handle it. When working with vertical, laying should be carried out in pairs. We also recommend working in pairs when laying horizontal surfaces, such as roofs. So having two people walking on the same weld roll will increase the downforce and give a stronger adhesion.